- HOME

- PRODUCTS INFO.

- EPS & Plastic (PS/PP/PE) Recycling System

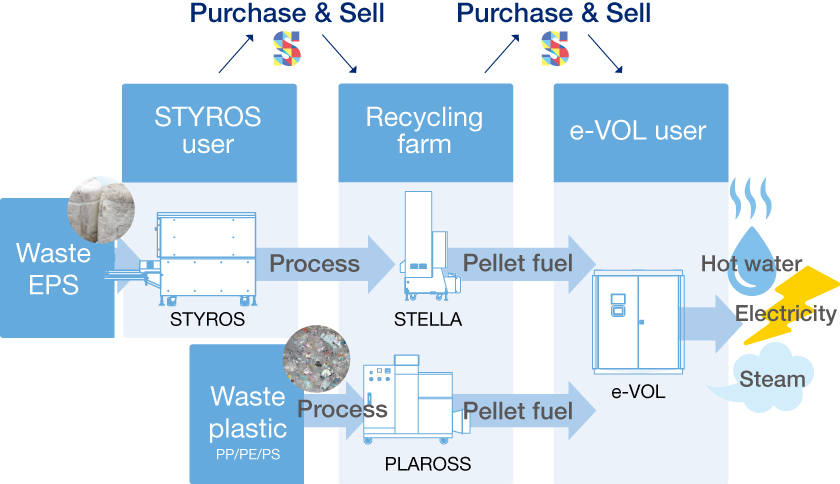

EPS & Plastics (PS-PP-PE) Recycling System

INTRODUCTION OF e-PEP

ECOLOGY

e-PEP system regenerates hot water from thermoplastic refuse. Waste to Energy! Save fuel cost as well as solve the plastic pollution issues.

ECONOMY

Resin pellet, e-PEL is eco-friendly inexpensive fuel. It reduces 30% fuel cost by just changing your fuel to e-PEL, and reduces 72~60% by pelletizing your own plastic refuse and using them as your new free fuel!

MERIT OF e-PEP

e-PEP is short for "e=ecology, P=Plastics, E=Energy, P=Pellets"

FEATURE OF e-PEP

e-PEP VIDEO CLIP

e-PEP SPECIFICATIONS

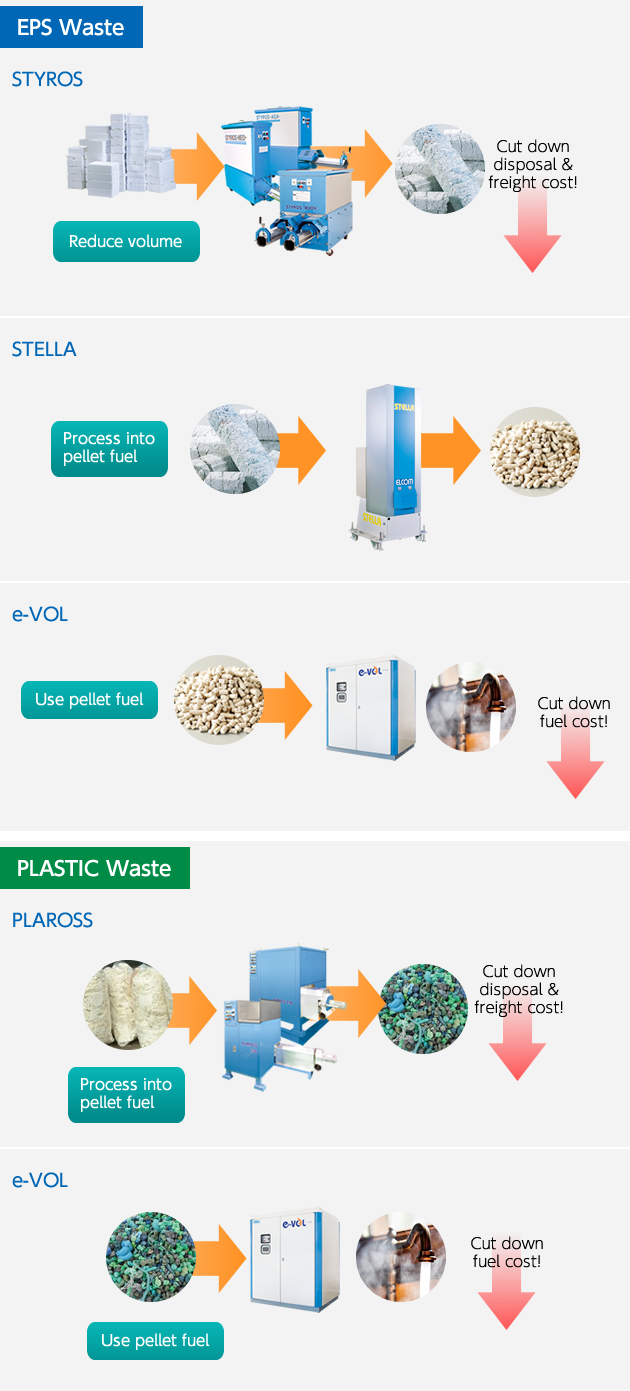

STYROS BUOY reduces volume of waste EPS such as boxes, cushioning materials or larger ocean floats. Volume reduction is up to 1:25. Save disposal & freight cost!

- High capacity(100㎏/h max.)

- No heat & solvent used! No Smell!

- 80% less Electricity ※compared with conventional compactor.

- Simple and easy maintenance

- Even wet EPS can be processed directly!

- Compact & mobile

| Name | STYROS-BUOY |

|---|---|

| Model | SB1-A |

| Capacity | 60〜100kg/h |

| Power | AC/three-phase 200V 7.4KW 50Hz/60Hz |

| Size(mm) | W810xL2181xH1330 |

| Operation | Switch Selecting method |

| Driving System | Biaxial Direct drive method |

| Safety Devices | main switch of breaker type, automatic reversal rotation, emergency stop button, safety timer |

| Compacting Rate | 1/5~1/25 |

| Weight | 750kg |

| Target Objects | EPS buoys/floats, EPS fish boxes, EPS cushioning |

Note: The above specifications are subject to change without prior notice for product improvement.

-

Expanded Polystyrene(EPS) Pelletizer STELLA

Pelletizing compressed EPS materials into pellet fuel. EPS pellets canimage be very beneficial to reducing fuel cost and preserving the environment.

- Regenarate waste EPS to pellet fuel!

- Almost equivalent calorific value to fossil fuel!

- Volume reduction is 1:40!

- Reduce freight cost & CO₂ !

- Easier to handle than kerosene!

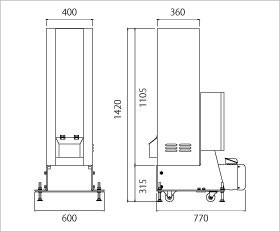

| Name | STELLA |

|---|---|

| Model | ST1-A |

| Capacity | 20~50kg/h |

| Power | AC/three-phase 200V 3.7kW 50Hz/60Hz |

| Hopper(mm) | W400xD360xH670 |

| Size(mm) | W600xD770xH1420 |

| Weight | 280kg |

| Pellet Size | φ8㎜ |

Note: The above specifications are subject to change without prior notice for product improvement.

-

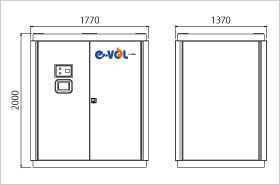

Resin fuel Pellet Hybrid Boiler e-VOL

The specialized boiler fueled by tne pellets made from waste PS/PP/PE, ensures reducing total running cost on fuel.

- PS/PP/PE pellets boiler to generate hot water!

- Passed the emission gas regulations in Japan!

- Hybrid combined in use of kerosene!

| Name | e-VOL |

|---|---|

| Boiler Type | Pressureless heat-releasing type |

| Output | 60,000kcal/h (70kW) |

| Main Fuel | PS/PP/PE pellets Fuel consumption approx.10kg/h |

| Alternative Fuel | Kerosene, fuel oil A |

| Temperature | 70~85℃ |

| Water Capacity | 200L |

| Size | W1770×D1370×H2000 |

Note: The above specifications are subject to change without prior notice for product improvement.

-

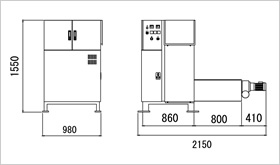

Thermoplastic resin Compactor PLAROSS

Reduce volume and pelletize thermoplastic resin materials, even the previously difficult-to-process bulky refuse, such as Foam material.

- Pelletize PE or PP film materials !

- Ideal for compacting foam sheets, bubble wrap materials!

| Name | PLAROSS |

|---|---|

| Model | PR-A100 |

| Capacity | 50~60kg/h |

| Power | AC/three-phase 200V 20.8kW |

| Size(mm) | W980×L2150×H1550 |

| Weight | 1200kg |

Note: The above specifications are subject to change without prior notice for product improvement.

e-PEL Flow Chart